- Rapid Liquid Print (RLP), a spin-off from MIT, secures $7 million in Series A funding from lead investor HZG Group, BMW i Ventures, and MassMutual.

- RLP’s new 3D printing technology operates inside a gel, producing large-scale, flexible products quickly, with a focus on automotive and medical sectors.

- HZG Group, based in Bavaria, invests in RLP to support its innovative additive manufacturing process, aiming to develop an industrial-scale production machine.

- RLP’s technology allows for the creation of complex and large-scale objects using sustainable materials, with the gel being reusable and materials recyclable.

- RLP’s printing factory near MIT uses the technology to serve various industries, including medical, automotive, and consumer goods, supported by a unique software platform for control.

Revolutionizing Additive Manufacturing with Liquid Print Funding

In the realm of additive manufacturing, innovation never ceases to amaze. One such groundbreaking development comes from Rapid Liquid Print (RLP), a startup that originated as a spin-off from the prestigious Massachusetts Institute of Technology (MIT) in 2015. Recently, RLP made waves in the industry by securing a substantial $7 million in series A funding, marking a significant milestone in its journey towards revolutionizing the world of 3D printing.

Series A Funding: A Game-Changer for Rapid Liquid Print

The latest round of financing for RLP was led by Germany’s HZG Group, a notable venture capital investor with a keen interest in cutting-edge technologies. Joining the lead investor were existing backers BMW i Ventures and MassMutual, underscoring the confidence and support RLP has garnered from its investors. Notably, BMW i Ventures holds a special place in RLP’s journey, as they were the startup’s inaugural seed investor, showcasing a strong belief in the company’s vision from the outset.

Schendy Kernizan, the co-founder and CEO of RLP, expressed excitement about the partnership with HZG Group, emphasizing the investor’s recognition of the immense potential of RLP’s technology. With plans to leverage HZG Group’s engineering expertise and network, RLP aims to propel its innovative solutions to new heights, particularly focusing on the development of industrial-scale machines to further enhance its offerings.

Related Video

Unveiling the Technology Behind Rapid Liquid Print

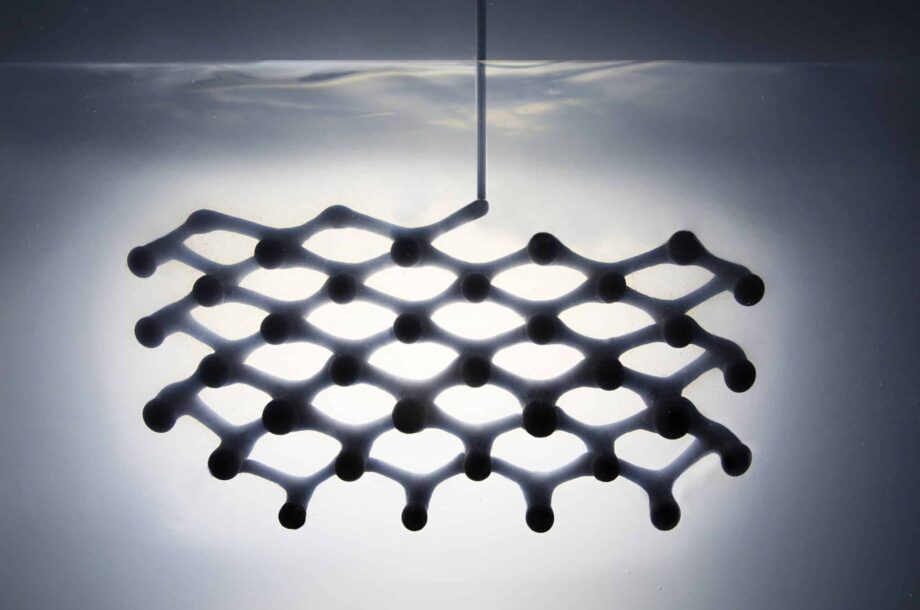

At the core of RLP’s innovation lies a cutting-edge 3D printing process developed at MIT’s Self-Assembly Lab. Unlike traditional additive manufacturing methods, RLP’s technology involves ‘drawing’ liquid objects within a gel suspension, resulting in the creation of large-scale, flexible, and robust products in a matter of minutes. By operating within a gel medium, RLP’s printers can produce complex geometries without the constraints of conventional layer-based processes, offering a new realm of possibilities in the realm of additive manufacturing.

The unique process employed by RLP involves injecting a liquid material mixture into a gel-filled container, where a gantry system draws the desired object into three-dimensional space through a precise nozzle. The gel suspends the object during printing, allowing for the curing process to take place seamlessly. Notably, the technology eliminates the need for additional support structures and post-processing, enabling immediate utilization of the printed objects without any additional steps.

Advancing Sustainability and Scalability in Additive Manufacturing

Beyond its innovative approach to 3D printing, RLP’s technology also champions sustainability and scalability in the industry. The ability to reuse the gel multiple times and recycle the print material at the end of a product’s lifecycle underscores RLP’s commitment to environmental responsibility. Moreover, the technology’s capability to create large-scale geometries using established materials opens up new avenues for industrial applications, promising significant advancements in the additive manufacturing landscape.

With the infusion of $7 million in series A funding, RLP is poised to scale production, expand its team of experts, and diversify its business areas to drive further innovation in the additive manufacturing sector. The strategic partnership with HZG Group, coupled with the support from industry stalwarts like BMW i Ventures and MassMutual, positions RLP for continued success and growth as it pushes the boundaries of what is possible in additive manufacturing.

Links to additional Resources: